Tips & Tricks: Laser Cutting "Frog Hopping" Technology

The cutting speed of the laser is the key to productivity. For large-scale industrial production, the small laser cutting head every point to improve the speed of movement, can make the whole cutting process efficiency, perhaps in the competitive laser cutting to stand out.

This movement speed not only depends on the laser processing power size, but also depends on the laser head movement path design is reasonable. In the cutting process, the laser head is in accordance with the written program for the movement, the whole process seems simple, in fact, also cohesion of the wisdom of engineers skills. For example, the development of "frog jump" technology, is in the practical application of the gradual summary.

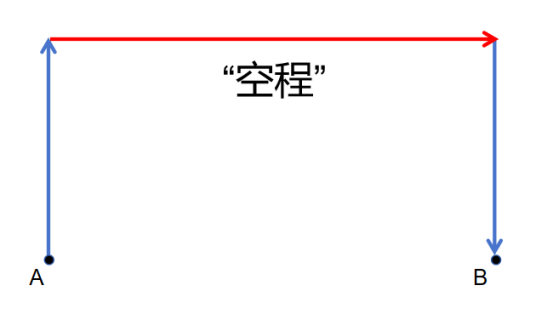

Frog Hopping is a simple efficiency improvement strategy. The technical principle is actually very simple. Early fiber laser cutting machine is not configured frog jump technology, if you want to punch holes in metal materials on the A, B two points successively, because the laser head movement over the need to leave the metal surface, it is necessary to let the laser head from the A point to start punching holes, punching is completed, lifted to a certain height to reach a certain height to reach A above the point, and then move horizontally to the top of the B point, and then fall to the B point to start punching holes, the whole process is very cumbersome.

The time during which the laser cutting head moves horizontally, known as "idle" time, is unnecessarily wasted.

Not equipped with frog jumping technique

In response to this, frog jumping technology has gradually been introduced. Simply put, it is to let the laser head from point A to point B in the process of completing the upward and downward operation. When the A point after the completion of punching, the laser head up at the same time to the B point movement; movement to A, B near the midpoint of the laser head to reach the highest point, and at the same time began to fall. When the downward movement is completed, the laser head moves to point B at the same time.

In this way, the movement of the trajectory of the "broken line" into a "diagonal line", three steps into two steps, shortening the path of the laser head movement, thereby enhancing the efficiency of the entire process. Since this path is somewhat like a frog jumping up high, catching its prey and then falling down, it is figuratively called the "frog jump" technique.

Equipped with frog jumping technique

Don't underestimate this little technological innovation. First of all, in large-scale sheet metal processing, the need for two intervals between the point of processing can be described as a lot of cases, if each frog jump technology can make the process faster 1 second, then for 6000 pieces of sheet metal, each piece of sheet metal are required to "frog jump" 60 times, then you can save 100 hours of labor, which is very considerable. Next, for large plates, the need to punch the A, B point may be far away from each other, one to two, with or without frog jumping technology, the gap between them is very large.

China's manufacturing industry "involution" status quo we all understand, and the laser cutting industry is more so. An enterprise production of laser cutting machine once equipped with frog jump technology, improved efficiency, other enterprises will quickly imitate, or will quickly be eliminated from the market. Soon, frog jump technology has become a fiber laser cutting machine "standard", which is also one of the laser processing technology upgrades on the road of countless updates.

Later, the technicians further optimized the process of "frog jump". In the frog jumping process, let the laser head accelerate until the highest point to reach the highest speed; in the descent process deceleration, until the B point stops, just can start processing. The actual processing is reflected in the "senseless start and stop", to avoid the loss of rapid stop and go.

Of course, the actual processing of the situation is often more complex, "flight cutting", "short distance without lifting" and other specific processing has been gradually applied to fiber optic cutting. It is such a subtle technical optimization, iteration, day by day, so that laser cutting gradually on the plasma cutting to establish an overwhelming advantage, but also the metal processing industry, such as the "frog jump" like over the barriers, break through the bottleneck.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்