The "brain" at the heart of next-generation laser cleaning is born! It could be the focus

Laser cleaning is known as the "21st century the most development potential of green cleaning technology", can not damage the substrate surface under the premise of the grain structure and orientation of the substrate surface changes, and can control the surface roughness of the substrate, so as to enhance the comprehensive performance of the substrate surface. Accompanied by the accelerated process of industrialization and "double-carbon" goal steadily advancing, in many fields gradually replace the traditional cleaning process, and gradually become an indispensable equipment manufacturing technology for industrial, military, shipbuilding, aerospace and other high-end manufacturing areas.

With the rapid development of the laser cleaning industry, the laser towards the direction of miniaturization of non-stop development, handheld, mobile laser cleaning equipment makes the laser cleaning technology to use a wider range of fields. In the laser head of the laser equipment is mostly used in the laser scanning galvanometer to realize the laser cleaning scanning range and scanning speed control. At present, the cleaning system is mainly divided into continuous laser cleaning system, pulsed laser cleaning control system, the domestic continuous laser cleaning system application is more common and mature, but pulsed laser cleaning system and continuous - pulsed composite cleaning system development is slower.

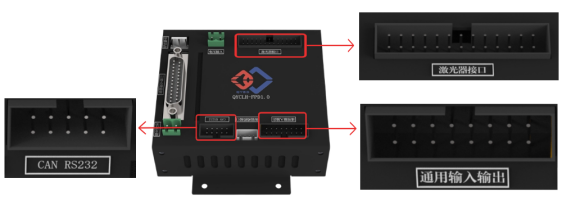

Sintec Optronics has independently developed a new generation of integrated control system for laser cleaning, developed special hardware circuits and embedded software to realize precise control of lasers and galvanometer systems, interaction of external electrical components and interaction of HMI devices, and the interface is not only applicable to domestic laser brands such as Raycus, but also to international brand lasers such as IPG. The interface is not only applicable to domestic laser brands such as Raycus, but also applicable to IPG and other international brand lasers. Support one-dimensional and two-dimensional vibration mirror, can be matched with handheld single pendulum laser cleaning, welding gun, also applies to swing cleaning, welding gun, in addition to the control board supports serial communication and bus communication, convenient for users to realize the automation integration, the system integrates 24V and ± 15V power supply, saving electrical costs and space saving at the same time. Controller volume of only 103 * 92.5 * 33.5mm, is currently the smallest, most versatile continuous - pulse laser cleaning universal composite control system, the system effectively enhance the cleaning efficiency, to solve the cleaning process linear ends of the "match head" problem, the system has been in the aerospace, The system has been used in aerospace, rail transportation, tire molds and other industries to achieve batch and stable application.

The integrated control system has the following technical advantages:

Dual motherboards, multiple interfaces, flexible and reliable

Dual-layer motherboard design, separated from the core general hardware and external interface hardware, in a unified development platform can develop multiple types of control capabilities, compatible with different types and manufacturers of lasers; at the same time equipped with flexible universal input and output interfaces to meet the needs of various types of customized control; the basic general communication interface to meet the requirements of peripheral communication, but also flexible expansion of the communication interface, to achieve a longer distance, Higher reliability of communication needs.

Integrated voltage control, one-stop solution for power supply needs

The control hardware adopts a single 24V power input interface, and other voltage requirements are integrated within the system, thus reducing the number of external switching power supplies, and the system's internal reliable power demand analysis and distribution strategy also reduces maintenance costs. At the same time, it is equipped with positive and negative 15V power supply output interface, which makes this control system can be used as control hardware and has the ability to drive the vibration mirror system externally, which is a one-stop solution for the control and power supply needs in the field of general-purpose laser cleaning.

Meet the diversified needs of process and external components

In order to meet the various types of vibration mirror hardware, the control system has both digital vibration mirror protocol signal output and analog drive signal output of the vibration mirror, so as to achieve both flexibility and unity, and to meet the selection needs of different external hardware. Scanner control module adopts dual-axis signal output, which greatly improves the diversified needs of customers for the process and broadens the process capability of the equipment.

High-speed chip + high-efficiency code, double effect superposition

Laser cleaning often requires highly efficient pulsed lasers and high-speed galvanometer to realize efficient cleaning needs. The core of the control system uses a high-speed chip, with high-efficiency code and algorithmic logic, which can further improve the frequency of vibration mirror coordinate signal transmission on the basis of meeting the general vibration mirror protocol, and at the same time can also reduce the coordinate interval, so as to achieve high-speed and delicate vibration mirror control, with high-efficiency pulsed laser, so as to realize a more delicate laser cleaning effect. On the other hand, the ultra-high-speed frequency also allows the chip to handle multiple types of external control requirements, such as data acquisition, external component control and inter-device communication, while handling the task of galvanometer movement.

The new generation of integrated control system combines highly integrated power management, galvanometer control, flexible universal input/output interfaces, and highly scalable communication interfaces; at the same time, with the customizable embedded software, it can truly solve the customer's needs for multiple types of equipment and complex processes. While achieving the above capabilities, the volume is only half of the usual control system or even smaller, making it more friendly equipment integration capabilities.

As an important force in the development of laser cleaning technology and equipment, Wuhan Sintec Optoelectronics Co., Ltd. focuses on the layout of high-energy pulsed lasers, control systems for cleaning and intelligent equipment, with a doctoral innovation team specialized in optics, mechanics, electronics, computers, materials science and other disciplines, in the field of laser cleaning/welding key core devices, process methods, intelligent control, complete sets of automation solutions and other fields. We have more than 50 core intellectual property rights at home and abroad, and more than 30 types/classes of laser cleaning core products.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்