WhatsApp: 15671598018 E-mail: info@SintecLaser.com

WhatsApp: 15671598018 E-mail: info@SintecLaser.com

This protective window is mainly used to protect the focusing lens. It can prevent trash from splash onto the lens and causing damage to the lens.

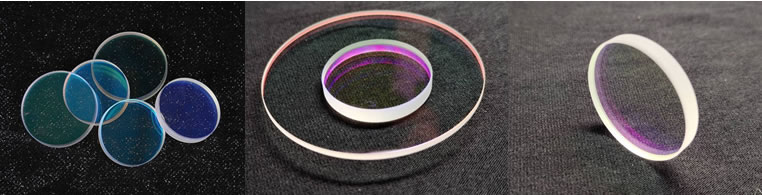

Laser protective windows are also called laser protective glasses/plates, laser dust-proof windows. This product is mainly used to protect the focusing lens. It can prevent trash from splash onto the lens and causing damage to the lens. However, it requires regular replacement of protective lenses to ensure the accuracy of laser processing. If you try to coat the windows with an anti-reflection coating films with a high damage threshold(>15Jcm2), it can effectively increase the transmittance of the windows, reduce the loss of laser energy, and improve the quality of processed products. This product is widely used in various laser processing equipment such as laser cutting machines (500-2000W), laser welding machines, laser marking machines and laser engraving machines.

All the windows we offer are made of high-quality quartz crystal materialsthroughcutting, grinding, polishing, coating. Similarly, we can customize various specifications of protective windows according to customer’s needs (diameter 20-100mm, thickness 1-9mm, diameter and thickness tolerances are ±0.1mm).

Features:

Made of high-quality quartz crystal material, ultra-thin windows, not easy to chip and crack

Double-side coated light-transmitting film (transmittance up to 99.5%)

Strong durability, high temperature resistance, strong anti-laser performance;

Wavelength up to 1064nm for a wide range of applications

45° protective full-angle design, safe and easy to use without hurting your hands

High light transmittance, strong anti-rubbish, long service life

General Product Specifications(1030-1090nm)

| Model | Wavelength | Diameter | Thickness | Material | Clear Aperture | Transmittance | Surface Quality | Parallelism |

| STSA-001 | 1064nm | 20mm | 2mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-002 | 1064nm | 20mm | 3mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-003 | 1064nm | 22.35mm | 4mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-004 | 1064nm | 24.9mm | 1.5mm | Quartz | <1 point | |||

| STSA-005 | 1064nm | 25.4mm | 3mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-006 | 1064nm | 25.4mm | 3mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-007 | 1064nm | 27.9mm | 4.1mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-008 | 1064nm | 28mm | 4mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-009 | 1064nm | 30mm | 1.5mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-010 | 1064nm | 30mm | 5mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-011 | 1064nm | 34mm | 5mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-012 | 1064nm | 35mm | 4mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-013 | 1064nm | 36mm | 5mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-014 | 1064nm | 37mm | 7mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-015 | 1064nm | 40mm | 2mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-016 | 1064nm | 42mm | 3mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-017 | 1064nm | 50mm | 2mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

| STSA-018 | 1064nm | 55mm | 1.5mm | Quartz | <80% | 99.5% | 40/20 | <1 point |

We can provide AR coating layers of any wavelength according to customer needs. If you have any specific requirement on diameter, thickness and coating, please contact us and we will also try our best to meet your needs.

A leading supplier and manufacturer of a wide range of photonics products such as lasers,laser parts & machines.

Office: 18 South Liu Fang Yuan Road, Sintec Industrial Park, Optics Valley of China, Wuhan Hubei, 430205 PR China

Tel: +86 27 51858962

Fax: +86 27 51858989

Whatsapp: 15671598018

E-mail: info@SintecLaser.com