New technology helps make laser glass welding practical

Ultra-short pulsed lasers combined with subtle self-focusing technology provide the quality and process reliability required to make laser glass welding applications for mass production possible. The unique and excellent properties of glass allow it to be used in a wide variety of high-tech products in different fields such as biomedicine and microelectronics. We have previously described the challenges it presents to manufacturers, particularly in the area of high-volume, precision glass cutting. It also presents bonding difficulties, including soldering individual glass components together, as well as soldering glass to other materials such as metals and semiconductors.

Fusing together

All of the traditional methods used to bond glass struggle to provide the precision, bonding quality and production speed needed for cost-effective mass production. Adhesive bonding, for example, is an economical method, but leaves adhesive residue on the part and even requires degassing.

Dielectric welding involves placing powdered material at the point of contact and then melting it to complete the bond. Whether this melting is accomplished by an oven or a laser, a lot of heat is pumped into the part. This is a problem for microelectronic devices and many medical devices.

Ion bonding is an ingenious method that provides extremely high bond strength. Two new and extremely flat glass surfaces are pressed together and literally fused together by molecular bonding. However, it is not practical to perform this operation in a production environment.

Laser Glass Welding

What about laser welding? Glass has a number of very useful properties, such as an extremely high melting point, transparency, brittleness and mechanical rigidity, but it also presents many difficulties for laser welding. As a result, the typical industrial lasers and methods used to weld metals and other materials are not applicable to glass.

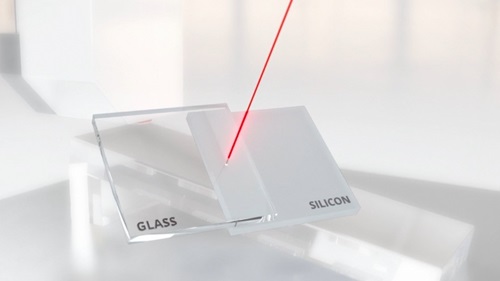

As with precision glass cutting, the secret lies in the use of infrared wavelength ultrashort pulse (USP) lasers. Glass is transparent in the infrared, so a focused laser beam passes right through it until the focused beam narrows and becomes so concentrated that it triggers a "nonlinear absorption". This "nonlinear absorption" only occurs with an ultrashort pulsed laser that has a high peak power, and it is not possible to accomplish the same thing with other types of lasers.

So, in a very small area (usually less than a few tens of microns in diameter) around the focal point of the laser beam, the glass absorbs the laser light and melts rapidly. This focused beam is scanned along the desired weld path to complete the bond, just like any other form of laser welding.

The USP laser glass welding method offers three main advantages.

First, it creates a strong bond because both materials being welded are partially melted and then solidified together to form a weld. Furthermore, the process is equally suitable for bonding glass to glass, glass to metal, and glass to semiconductors.

Second, in this process, only a very small amount of heat enters the component, generating this heat over an area at most a few hundred micrometers wide. This allows the weld to be placed very close to electronic circuits or other heat-sensitive components, which provides designers and manufacturers with greater freedom and supports better product miniaturization designs.

Finally, if USP laser glass welding is performed properly, microcracks will not develop around the weld seam. Microcracks reduce the mechanical strength of the glass. In addition, after temperature cycling, which is inevitable for everything, microcracks can be the source of eventual equipment failure.

Sintec optronics Put USP Laser Glass Welding to Work

The advantage of USP laser glass welding stems from the fact that the glass is heated only in a very small volume. But it also poses practical challenges. This means that the laser focus position must be held very precisely at the interface between the two welded components, even if the part moves. Since real-world components are not perfectly flat, this is difficult to achieve. In addition, the position in which the components are placed in the welding system may not be an exact fit.

One solution is to use an axially elongated focal point. This "stretches" the size of the laser beam focal point to address position sensitivity. However, the disadvantage of this approach is that the elongated beam focus creates a melt pool in the glass with a non-circular cross-section. As the glass solidifies in the melting zone, the non-circular pool is more prone to microcrack formation.

SintecOptronics uses an alternative approach to achieve microcrack-free welding results that can simultaneously accommodate significant changes in interface distance during the process. The secret lies in the combination of highly dynamic focusing technology that utilizes high numerical aperture (NA) optics to produce a small focal spot.

As a result, SintecOptronics laser system achieves a highly spherical molten pool that avoids microcracking. It also senses the interface distance and continuously adjusts the optics so that perfect focus is always maintained. The result is a high-quality weld that is guaranteed on virtually any shape and a process that is independent of component tolerances and position.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்