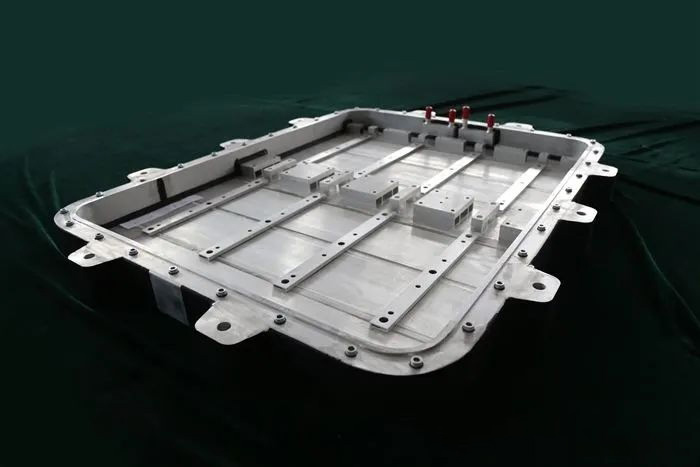

10 Key Technologies in Laser Cutting for NEV Battery Trays

Introduction: A 0.02mm Precision Revolution

In 2023, Tesla's Berlin Gigafactory silenced alarm bells – its new laser cutting line achieved 99.8% yield for battery trays. This milestone redefines EV manufacturing. Explore the 10 core technologies driving this transformation.

Ten Pillars of Technological Leadership

1. Surgical Positioning System

0.05s 3D modeling via radar + machine vision

CATL case: ±0.03mm accuracy on deformed aluminum

3600% efficiency gain over mechanical systems

2. AI Energy Conductor

Real-time power adjustment for 8mm Al vs 0.5mm Cu

VW MEB line speed reaches 20m/min

3. Nano Armor Protection

TiN coating extends nozzle life to 2000hrs

BMW Leipzig saves €150k/year

4. Light Orchestra

| Light | Orchestra | Material Solution Breakthrough |

| Aluminum alloy | 1064nm pulsed fiber | HAZ reduced by 87.5% |

| Cu-Ni composite | Green+blue hybrid | 3x speed increase |

| Stainless seals | Picosecond ultrafast | Ra<0.4μm surface |

5. Industrial Air Surgeon

98.5% dust recovery with cyclone tech

BYD achieves ISO Class 5 cleanrooms

6. Digital Prophet

48hr virtual trials cut 83% waste

Hyundai slashes NPI time from 7d→8hr

7. 5G Quality Guardian

Detects 0.015mm flaws (red cell size)

LG Energy Solution: Zero defects for 90 days

8. Maglev Speedster

5G acceleration (space launch level)

68% energy saving certified

9. Self-healing Optics

Autonomous damage repair in 72hrs

ISS component test passed

10. Global Process Brain

3 million parameter database

Renault-Nissan saves €4.8M/year

Conclusion: Cutting the Future

From Tesla to CATL, laser cutting is rewriting EV manufacturing DNA. These innovations deliver:

35-60% cost reduction

40x faster new product launch

75% lower environmental impact

Sintec Optronics has empowered NEV makers in 23 countries. Contact our engineers today to unlock zero-defect manufacturing! For more further information, pls click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்