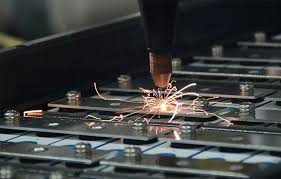

Laser Welding Revolution in Power Battery Manufacturing: From Cell to PACK Integration

Amid the explosive growth of new energy vehicles, laser welding has become the "gold standard" for power battery manufacturing with its 30% deeper penetration and 50% less thermal deformation compared to traditional processes.

Ⅰ. Mid-section Cell Assembly Revolution

Laser welding penetrates four critical nodes:

Can Sealing: Fiber lasers achieve 0.1mm-level seams with hermeticity ≤10⁻¹¹ Pa·m³/s

Cap Welding: Vision positioning ensures ±0.05mm precision, yield rate reaches 99.8%

Filling Port Sealing: Pulse laser controls heat input <50J/cm², preventing electrolyte contamination

Ultra-thin Tab Welding: Beam oscillation technology solves brittle phase issues for 0.2mm Cu-Al dissimilar materials

Case: CATL's 5-series battery line uses blue lasers (450nm) to increase copper absorption by 60% at 120mm/s welding speed

Ⅱ. PACK Module Integration Breakthroughs

Three key advancements in module stage:

1. Multi-material Connector Welding

Cu-Al joints with hybrid welding (Laser+MIG) achieve tensile strength >120MPa

Busbar deformation <0.1°

2. Precision Bursting Disc Welding

0.3+0.3mm Al sheets welding

Burst pressure stabilized at 1.5±0.2MPa (meets GB 38031-2020)

3. CTP/Blade Battery Integration

Beam shaping enables 8:1 aspect ratio for 8-layer foil penetration

Ⅲ. Techno-economic Advantages

| Metric | Traditional | Laser Weling | Improvement |

| Cycle Time | 0.8s/point | 0.25s/point | 68.75% |

| Yield Rate | 92.5% | 99.3% | 7.3% |

| Energy Cost | $0.45/m seam | $0.15/m seam | 66.7% |

Forecast: With 3μm beam shaping optics and AI weld monitoring, laser welding penetration in battery manufacturing will exceed 85% by 2025 (2023: 62%). For more further information, pls click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்