Laser Marking Machine Buyer's Guide

As industrial manufacturing becomes precision and personalized, laser marking technology is widely used in electronics, hardware, medical, automotive, packaging, jewelry and other fields with its advantages of high efficiency, high precision and permanent marking. However, faced with a wide variety of laser marking machines on the market, companies often find it difficult to choose when purchasing. So, how should you choose a laser marking machine? This article will sort out a set of practical selection ideas for you.

1. Clarifying the material type is the first step in selection

Different types of laser marking machines are suitable for different materials:

Fiber laser marking machine: suitable for metals and some hard plastics, it is the most widely used at present, such as stainless steel, aluminum, copper, ABS, PEEK, etc.;

UV laser marking machine: short wavelength, suitable for heat-sensitive materials such as glass, crystal, plastic film, ceramics, etc., with fine marking and smooth edges;

CO₂ laser marking machine: suitable for non-metallic materials such as wood, leather, paper, cloth, acrylic, etc.;

Green laser marking machine: strong compatibility, suitable for some metals, glass and polymer materials, especially in the lithium battery and PCB industries.

2. Clearly see the laser power to determine the processing efficiency and effect

The laser power directly affects the speed, depth and clarity of marking. Generally speaking:

Low power (such as 10W, 20W) is suitable for fine marking, QR code, LOGO, etc.;

Medium power (such as 30W, 50W) is suitable for deeper marking and light engraving;

High power (≥100W) can be used for deep engraving, large-area marking or thin plate cutting.

Users should choose the power according to product requirements, production line rhythm and process standards to avoid "over-configuration" or "insufficient performance".

3. Identification system configuration is related to stability and operating experience

A high-quality laser marking system should have the following core components:

Laser brand and life: imported light sources (such as IPG, Coherent) and domestic mainstream brands (such as Maxphotonics, Raycus) have their own advantages, which need to be evaluated according to the budget;

Galvanometer scanning system: determines the marking speed and accuracy, and high-speed scanning galvanometer can effectively improve the efficiency of the production line;

Software system: user-friendly interface, good compatibility, support for multiple languages and multiple vector file formats, is the guarantee of marking flexibility;

Cooling system: air cooling or water cooling scheme needs to match the power to ensure long-term stable operation of the equipment.

4.Pay attention to after-sales and service to ensure worry-free use

Purchasing a laser marking machine is not only about purchasing a piece of equipment, but also about choosing a long-term service partner. High-quality after-sales service should include:

Quick response mechanism;

Free training and remote support;

Complete spare parts and timely maintenance;

Software upgrade and function customization capabilities.

Choosing brands and agents with industry experience and good customer reputation will greatly reduce the risk of operation and maintenance in the future.

5.Tailor-made and opening up the process chain is the future trend

With the in-depth advancement of intelligent manufacturing, more and more companies hope that laser marking machines can be perfectly integrated with production line MES systems, automatic loading and unloading systems, and visual recognition equipment. Customized automated marking workstations and assembly line linkage solutions have become the first choice for large factories or automation integrators.

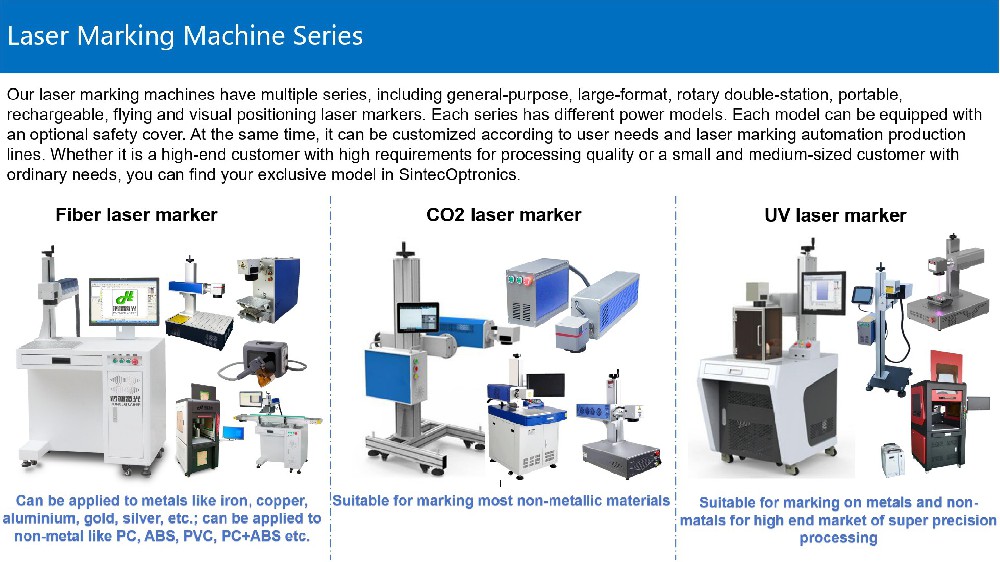

SintecOptronics is the source manufacturer of all-category and full-scenario laser processing equipment around you, specializes in customizing intelligent equipment such as laser cutting, welding, marking, cleaning, quenching and cladding machines, and provides customers with customized laser automation equipment and production lines. Our laser marking machines have multiple series, including general-purpose, large-format, rotary double-station, portable, rechargeable, flying and visual positioning laser markers. Each series has different power models. Each model can be equipped with an optional safety cover. At the same time, it can be customized according to user needs and laser marking automation production lines. Whether it is a high-end customer with high requirements for processing quality or a small and medium-sized customer with ordinary needs, you can find your exclusive model in SintecOptronics.

The selection of a laser marking machine is a comprehensive project. It is necessary to pay attention to technical parameters as well as actual process requirements and long-term operating costs. It is recommended that users refer to sample marking tests before purchasing, clarify their product materials, production rhythms, and process standards, and fully communicate with experienced equipment suppliers to select a laser marking equipment that is truly "suitable for themselves".

If you have further selection requirements for laser marking machines, please contact us, and we will provide one-to-one professional consultation, more further information pls click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்