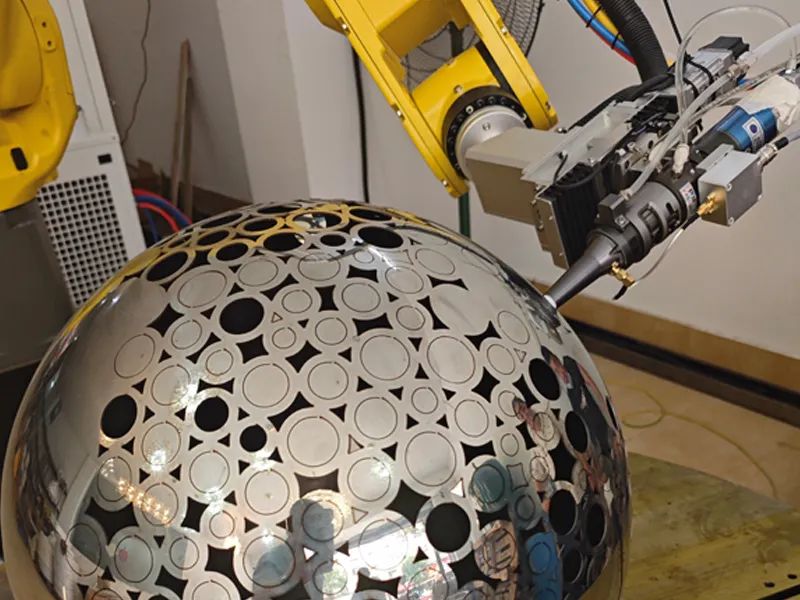

Robotic 3D laser cutting of sphere

In today's rapid development of urban renewal, rural revitalization and cultural tourism economy, landscape sculpture is quietly becoming an important carrier for urban image shaping and aesthetic enhancement of public space. Especially the sphere shape, which usually carries the concepts of science and technology, the universe, nature, etc., it's widely used in urban roads, parks and squares, science and technology exhibition halls and other scenes because of its strong visual tension and artistic expression, the symbolism is rich. However, the sphere sculpture faces many problems in the actual production process. Its surface curvature changes in complexity, cutting and welding precision requirements are much higher than the plane or simple geometric workpieces, the traditional manual cutting or mold molding method is difficult to adapt to the spherical structure, there is often a poor fit, splicing error, modeling is limited, and other issues, almost unable to meet the high precision, high efficiency, personalized design needs.

Most of the sphere sculpture projects are customized, and the batch production is small with different sizes, irregular structures and tight schedules, which are obviously not suitable for the use of traditional molds or mass production processes. With the continuous maturation of intelligent manufacturing technology, robotic 3D laser cutting machine gradually appeared in the sculpture industry's vision, especially in cutting of the sphere stainless steel, aluminum alloy and other metal shells to show a strong process capability, it's becoming an important technical support for landscape design from the conception to the reality.

Robotic 3D laser cutting machine opens up a new process for sphere processing

Faced with metal spheres with complex structures and high processing precision, the robot 3D laser cutting machine has demonstrated subversive advantages with its high flexibility and stable precision, providing a new choice for the field of spherical craft cutting. With its full range of 360° cutting capabilities, it bids farewell to cumbersome processes and unlocks the infinite possibilities of creative shapes to be "cut" at will. It is particularly suitable for the cutting and opening of spheres with irregular geometric structures:

1. Flexible 7-axis linkage, accurately follow the curvature of the sphere surface

Traditional cutting process is limited by the physical structure, it often can only deal with plane or simple oblique local processing, robotic 3D laser cutting machine combined with 6-axis industrial robots and rotary translators, constituting a 7-axis linkage structure, which can realize 360 ° omni-directional spatial cutting, accurately follow the curvature of the surface of the sphere for trajectory planning, and support multi-angle beveled port, shaped window, skeleton modeling and other complex processes, even facing a large metal sphere with a diameter of more than two meters, the 3D robotic laser cutting machine can also stably perform the entire map of the sub-flap cutting task, to achieve seamless splicing fine cutting. For designers, it means that they can really get rid of the process constraints, so that the complex modeling design can be accurately restored.

2. Small thermal impact, smooth edges without burrs

In the manufacturing process of metal sphere sculptures, the quality of cutting directly determines the structural strength and visual beauty of the finished product. Compared with traditional thermal processing methods such as flame and plasma cutting, the robot 3D laser cutting machine uses a high-energy laser beam to perform non-contact processing on the surface of the sphere. The cutting seam is extremely narrow and the heat-affected zone is extremely small, which can effectively avoid material deformation, cracks or internal stress concentration caused by high temperature. At the same time, there is no need for secondary grinding, which greatly saves labor processing costs and improves welding fit and overall aesthetics. For example, when processing a mirror stainless steel sphere with a diameter of 2 meters, it only takes 40 minutes to complete all the petal cutting. The cutting edge does not require any mechanical grinding and can directly enter the assembly stage, which greatly shortens the construction cycle. For a technological perspective, it is a processing capability that directly improves the quality of the finished product and the degree of design restoration. This is also the fundamental reason why more and more landscape sphere sculpture projects are turning to robot 3D laser cutting.

3. One machine for multiple uses, compatible with multiple sizes and materials

In order to cope with the diverse needs of customized processing, the robot 3D laser cutting machine has excellent size compatibility and can stably and efficiently support multi-specification cutting tasks from small spherical shell parts to large structural spheres. The cutting path can be automatically adjusted according to the diameter of the sphere, with strong adaptability, and can process landscape spheres with diameters ranging from 200mm to 2000mm or even larger. By programming to quickly switch the cutting path and precise trajectory control and stable spot output, the segmented continuous cutting of the entire unfolded drawing can be completed, one-time scheduling and efficient cutting of parts of different sizes can be achieved, which greatly improves the project execution efficiency and artistic restoration. The processing process always maintains extremely high precision while ensuring that there is no slag or overburning on the edge. In terms of materials, the equipment compatibility is also excellent. Common metal materials such as stainless steel, aluminum alloy, titanium alloy, copper, etc. can achieve high-quality cutting, truly achieving one machine for multiple uses, batch and single piece compatibility, adapting to various sculpture engineering needs, and creating more possibilities for the integration of landscape art and industrial manufacturing.

4. Compatible with multiple input formats, fast changeover, and high-frequency creative changes in sculpture processing

As an industry where "non-standard customization" is the norm, the design drawings of landscape sculptures are frequently updated. Traditional processing methods often rely on manual drawing and cumbersome programming. Once the design is adjusted, the entire process needs to be reconfigured, which is time-consuming and laborious. The robot 3D laser cutting machine shows strong adaptability in this regard. It supports to import multiple mainstream modeling formats, including STEP, IGES, DXF, DWG, 3D STL, etc. It can not only seamlessly connect with mainstream CAD/CAM modeling software (such as SolidWorks, UG, Rhino, etc.), but also can realize one-click import - automatic identification - path generation through the laser processing path automatic generation module. Whether it is cutting a small sphere or a multi-petal assembly structure of a super-large sphere, you only need to change the processing program without any hardware adjustment to quickly switch to the cutting task of the new graphic, truly realizing the "what you see is what you get" rapid manufacturing process, which greatly meets the non-standard customization and small batch diversified production tasks in sculpture art, greatly reduces the preliminary preparation work, and provides strong support for the rapid implementation of creative design.

A bridge between creative implementation and industrial upgrading

Landscape sculptures are not cold steel piles, but expressions of urban temperature and culture. With the support of robot 3D laser cutting technology, the manufacturing process of landscape spherical sculptures is undergoing a qualitative change. It not only simplifies the traditional complex cutting process, but also improves the modeling expression and artistic restoration, building a "visible and tangible" bridge between creativity and reality. Robotic 3D laser cutting machines have greatly liberated the creative freedom of artists. Artistic ideas that were shelved in the past due to complex structures and high costs are now gradually being implemented with the help of this intelligent manufacturing tool. Robotic 3D laser cutting machines not only lower the threshold for creation and improve processing efficiency, but also expand the formal boundaries of landscape sculptures, providing a new paradigm of intelligent manufacturing for the deep integration of cultural industries and manufacturing industries. For more further information, pls click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்