3D Laser cutting machine replaces traditonal helmets manufacturing process perfectly

As we all know, helmet is the key protection to secure the safety of our heads in our daily lifes and various application scenarios, its importance is self-evident. With the development of the technology and the diversification of the scenarios, the types of hemets are increasing, the manufacturing processes have been constantly innovated as well. From materials to functions, from design to manufacturing, the helmet industry is undergoing a profound technological transformation, especially for the manufacturing process, holes cutting and edges trimming seem simple, but they’re actually the key processes, these 2 processes are updating and transforming from traditional manual process to intelligent laser process.

The helmet types:

As the protective equipment, the helmets have already develop a complete product system which covering multiple fields:

1. Classified by materials:

Carbon fiber helmets: Carbon fiber meterial is of light weight and with high strength, it has excellent impact resistance, it’s expensive but with outstanding protection. It widely used in high-end motorcycles, racing helmets, aerospace and other fields that require extremely high for helmet performance.

Fiberglass (FRP) helmets: FRP helmets offer excellent overall performance, combining strength with toughness. Their price lies somewhere between ABS and carbon fiber helmets. They offer excellent value for money while maintaining effective protection. They are commonly used in applications where protection is essential but budgets are limited, such as industrial helmets and mid-range and low-end motorcycle helmets.

Kevlar helmets: Kevlar is an aramid fiber material, an engineering fiber with high strength, high modulus, and high toughness. It is five times stronger than steel, yet much lighter, and is much more difficult to process than thermoplastics like ABS and PC. Kevlar's excellent bulletproof and puncture-resistant properties make it widely used in body armor, helmets, and tactical equipment.

Engineering plastic helmets: ABS plastic and PC (polycarbonate) offer excellent formability and impact resistance, and are relatively low-cost, making them common helmet materials. Their hardness provides a degree of resistance to external impact, making them widely used in helmets for electric vehicles, motorcycles, and some industrial helmets.

Metal helmets: Ancient helmets were often made of metals such as bronze and iron. They were sturdy and durable, effectively protecting against attacks from cold weapons. Today, metal helmets are still used in certain areas, such as explosion-proof helmets. For example, police explosion-proof helmets are made of metal that can withstand significant impact, protecting officers' heads during dangerous missions.

2. Classified by Purpose

Motorcycle helmets: Motorcycle helmets are designed specifically for motorcycle riding and must meet the protection needs of high-speed riding. They have high requirements for material selection, structural design, and safety standards. For example, they must provide excellent impact resistance, wind resistance, and a certain level of sound insulation to ensure the safety and comfort of the rider's head during high-speed riding.

Electric bicycle helmets: With the increasing popularity of electric bicycles, demand for electric bicycle helmets is growing. While safety standards are slightly lower than those for motorcycle helmets, they must also comply with relevant regulations to ensure effective head protection at normal riding speeds. Furthermore, their design emphasizes comfort and convenience to accommodate the daily habits of electric bicycle users.

Sports helmets: These helmets cover a wide range of sports, including cycling, skiing, skateboarding, and equestrianism. Helmets for different sports are specifically optimized based on their characteristics. They offer lightweight construction yet high protection. For example, bicycle helmets emphasize lightweight and ventilation to reduce riding burden and keep the head cool. Ski helmets emphasize warmth and side impact protection, adapting to the snowy environment and the collision risks associated with skiing.

Industrial safety helmets: Industrial safety helmets are used in various industrial operations, such as construction, mining, and power maintenance. In addition to basic impact resistance, industrial safety helmets must also meet the needs of specific operating environments, such as fire protection, anti-static, and puncture resistance, to protect workers' heads in complex and dangerous industrial environments.

3. Classified by Function

Full-face helmets: Full-face helmets provide comprehensive head protection, including the crown, face, and chin. They offer optimal protection and effectively reduce the risk of serious head injuries during high-speed driving or high-risk work environments. Motorcycle racers, stunt performers, and others often use full-face helmets, providing comprehensive and reliable head protection.

3/4 helmets: These helmets protect three-quarters of the head, covering the top of the head and most of the face, but leaving the chin exposed. They offer a balance of protection and breathability and are commonly used in everyday riding. For cyclists who prioritize protection while also wanting a certain level of ventilation, 3/4 helmets are a good choice.

Half-face helmets: These helmets provide protection only to the top of the head and are the simplest type of helmet. They are easy to wear and offer good breathability, but their coverage is limited, making them primarily suitable for low-speed riding, such as short-distance e-bike riding. However, due to their limited protection, they lack adequate head protection at high speeds or in complex road conditions.

Flip-up helmets: Flip-up helmets can be considered a variation of full-face helmets, with the chin bar flipped upward to convert from full-face to three-quarter-face configuration. This design offers convenience for users with larger heads or those who frequently don and take off their helmets, ensuring adequate protection while increasing flexibility when wearing. For example, some motorcyclists often stop to communicate or navigate traffic during urban riding, and flip-up helmets can accommodate their need for constant adjustment.

Traditional Helmet Manufacturing Process and Pain Points

In traditional helmet manufacturing, after the helmet shell is formed, post-processing processes such as drilling holes (such as ventilation holes and screw holes) and trimming (such as trimming the bottom edge) are required to ensure wearing comfort and functional performance. Holes are typically cut by using mechanical drilling or die stamping. Die stamping is more efficient for simple shapes and regularly arranged holes. A die matching the hole shape is first manufactured and then stamp it holes onto the helmet blank by using a press. Mechanical drilling is often used for holes with irregular shapes or unusual locations. Workers use handheld drilling tools to manually drill holes according to pre-marked locations and dimensions. This method relies on the worker's experience and skill, requires frequent positioning, is cumbersome, and can't guarantee the accuracy and consistency of each hole. For full-face helmets with complex curved surfaces, a single helmet takes 15-20 minutes to process, and there are problems such as large dimensional deviations (often exceeding 1mm) and many burrs on the edges. Trimming is mainly done manually, with workers using tools such as files and sandpaper to polish and trim the edges of the helmets. First, use a file to initially remove excess material from the edge of the helmet to roughly shape it, and then use sandpaper of different mesh sizes to polish it in sequence to make the edge smooth and flat. In some mass production factories, simple mechanical trimming equipment such as grinding wheel grinders are also used, but they still require manual assistance, which requires high technical skills of workers and is relatively inefficient.

These processes were adequate in an era of low production capacity and small batch sizes. However, with the current trend toward high-variety, small-batch, and personalized consumer goods, their drawbacks are becoming increasingly apparent. These drawbacks are primarily manifested in the following ways:

High Cost: Mold development and labor contribute significantly to production costs, requiring multiple sets of molds for each new helmet. Furthermore, these molds often lack the ability to adapt to varying curvatures, leading to material stretching and deformation during cutting.

Lack of Precision: Whether cutting holes or trimming edges, traditional processes are subject to significant human influence, resulting in various quality for different workers. Manual labor makes it difficult to ensure that the hole position, size, and edge shape are perfectly consistent across helmets, resulting in inconsistent product precision and inaccurate hole placement, which can hinder assembly and even weaken structural strength. Given the extremely high safety requirements for helmets, these variations in precision can impact the overall protective performance and stability of the helmet.

Low efficiency: Traditional hole cutting and trimming processes are complex and cumbersome, especially with many manual steps. Manual operations are time-consuming and labor-intensive, unable to match the rhythm of automated production lines and difficult to meet the requirements of rapid delivery, thus restricting the company's production scale and market response speed.

High material loss: During manual operation, complex curved surfaces require multiple positioning, making it difficult to precise control . Mechanical drilling can easily cause composite helmets to fuzz and snag, damaging the integrity of the material and affecting the helmet's protective performance. Manual operation is difficult to ensure the accuracy and consistency of holes, and is prone to excessive grinding or cutting errors, resulting in low pass rates, high scrap rates, and frequent rework. Furthermore, during the mold stamping process, a large machining allowance is often required to ensure the mold's service life, further increasing material loss and raising production costs.

There are many safety hazards: high-speed rotating tool operation poses a risk of injury to personnel. Workers perform manual hole cutting and trimming operations for a long time, which is labor-intensive and prone to fatigue. This not only affects work efficiency and product quality, but also produces toxic gases due to thermal cutting, which also causes certain damage to workers' health and increases the company's employment risks and management costs.

Core Advantages of Laser Cutting Technology

In recent years, demand for helmets has rapidly increased across various sectors, including cycling, electric bicycles, motorcycles, police, tactical, and industrial safety. Consumers not only demand robust helmet protection but also seek added value such as lightweight, ergonomic, and personalized design. Facing the pain points of traditional processes, laser cutting demonstrates significant advantages in efficiency, precision, flexibility, and safety. With the maturity and widespread adoption of laser technology, laser cutting is gradually replacing traditional processing techniques and becoming a key trend in helmet post-manufacturing. The core advantages of laser cutting in helmet processing include:

Flexible Processing: Helmets come in a wide variety of styles and hole positions. Lasers can cut virtually any helmet material. Through offline programming or 3D mapping, modifications can be made without changing molds or tools, eliminating high mold costs. The same production line can simply switch programs to produce customized hole patterns for different helmets, enabling rapid response to new product development and particularly well-suited to the "high-variety, low-volume" manufacturing trend.

High Laser Precision: Laser cutting accurately identifies the 3D contours of the helmet shell and locates holes, minimizing errors and ensuring consistent hole locations. This effectively avoids the positioning errors and offsets associated with traditional punching, making it more user-friendly for assembly components such as rails, buckles, and bolts, and reducing assembly rework.

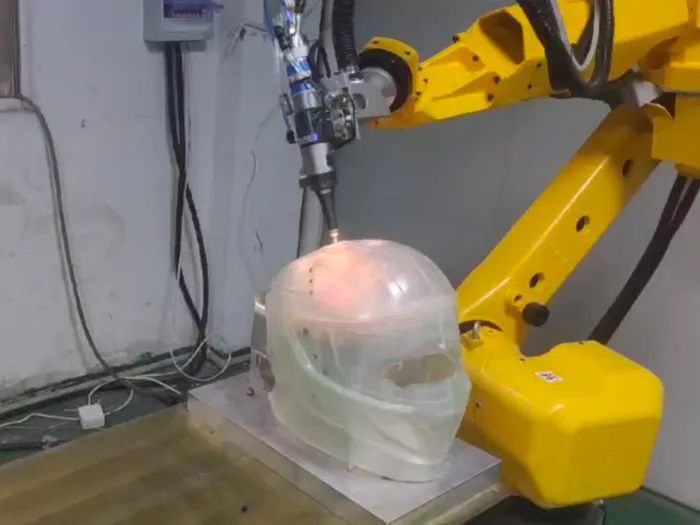

Beautiful incision: Helmet shells are often made of high-performance materials such as ABS, PC, Kevlar, and carbon fiber. These materials are difficult to process with traditional machinery, and usually cause flash, burrs, and even peeling between material layers. Laser cutting is a non-contact thermal energy processing method that has no mechanical pressure on the material, does not damage surrounding materials, has no microcracks, and no chipping. The cut edges are neat and beautiful, maintaining the integrity of the shell strength. After cutting, it can directly enter the spraying and assembly process, eliminating the need for grinding and polishing. It is particularly suitable for the processing of high-performance bulletproof materials (such as Kevlar and aramid composites).

High degree of automation: The laser system can be integrated with robots, positioners, and assembly lines to create highly automated, flexible production lines. Automatic clamping and cutting position recognition eliminate the need for human intervention, allowing for 24 hours fully automated continuous processing, significantly reducing labor costs, processing time, and material waste.

Environmentally friendly: Laser cutting generates no dust or flying chips, requiring no frequent component replacement or site cleanup. It eliminates the need for manual tools, avoids workplace injuries caused by high-speed saw blades, eliminates consumables costs, and reduces energy and noise, fostering a clean and safe working environment.

The Differences and Relationships Between Robotic 3D Laser Cutting Machines and 3D Five-Axis Laser Cutting Machines

In helmet manufacturing, laser cutting is primarily used for post-processing processes such as hole cutting, trimming, custom-shaped perforation, and slotting. It is suitable for a variety of shell materials, including ABS, PC, FRP, and Kevlar. Based on their form and function, there are two main types of laser cutting systems commonly used for helmets: robotic 3D laser cutting machines and 3D five-axis laser cutting machines. They are driving the helmet industry towards intelligent, flexible, and precision manufacturing. Although they both belong to 3D laser processing category, they differ significantly in their structural composition, processing methods, and applicable scenarios.

1. Structure

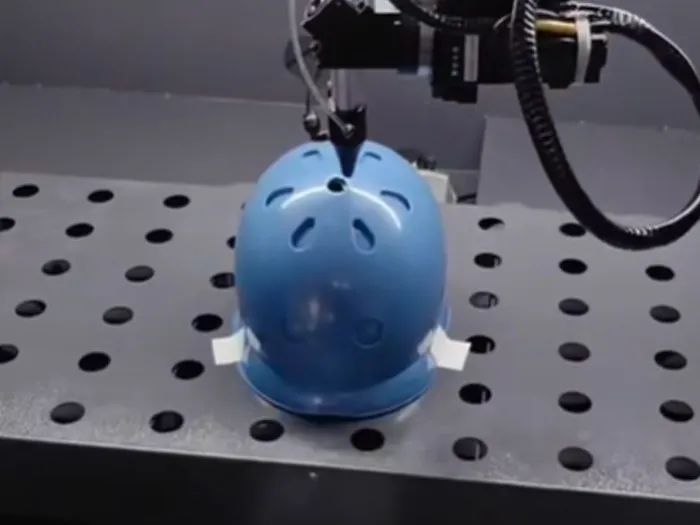

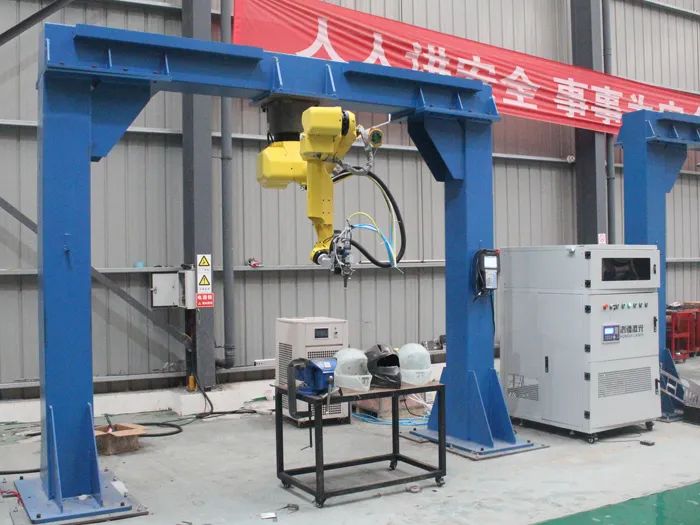

A robotic 3D laser cutting machine consists of a six-axis industrial robot equipped with a high-precision fiber laser system, enabling free-form cutting along any path in three dimensions. It is typically combined with a multi-axis positioner (rotary axis) and fixtures to create a 7 or even 8-axis linkage system, offering exceptional flexibility.

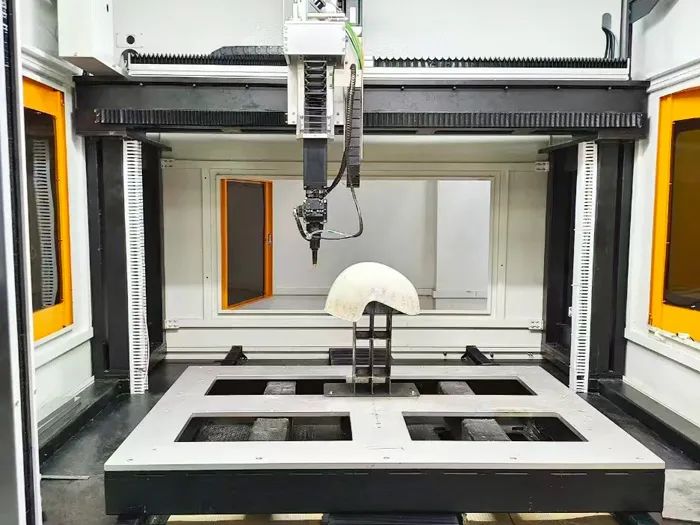

The 3D 5-axis laser cutting machine adopts a traditional machine tool structure, such as gantry type and cantilever type, with a built-in 5-axis linkage CNC system (X/Y/Z linear axis + A/C or B axis rotation), and realizes 3D cutting with a high-precision drive system and laser head control.

2. Cutting Range and Complexity:

Robotic 3D laser cutting machines are suitable for cutting helmets of most common shapes and moderate complexity. They offer flexible cutting operations within three dimensions, meeting common needs for hole cutting, trimming, and processing simple curved surfaces. However, their cutting capabilities are limited when dealing with extremely complex 3D surfaces and helmets with unusual spatial structures.

3D five-axis laser cutting machines are specifically designed for helmets requiring complex surfaces and high precision. Leveraging the advantages of five-axis motion, they can easily handle cutting tasks involving a wide range of complex shapes, from intricately designed sports helmets to industrial helmets with specialized protective structures. Or other fields like aerospace and high-end racing, where helmet performance and appearance are extremely demanding, 3D five-axis laser cutting machines possess significant advantages, enabling complex processes that are difficult to achieve with robotic 3D laser cutting.

3. Equipment Cost and Maintenance

Robotic 3D laser cutting machines offer relatively low equipment costs, simple structure and operation, and minimal maintenance. For enterprises adopting robotic 3D laser cutting equipment, the initial investment is relatively low, and the maintenance costs are manageable. The simple operation of the equipment allows these enterprises to quickly train skilled operators, which reducing training costs as well.

Due to its advanced five-axis linkage technology and high-precision optical system, 3D five-axis laser cutting machines have relatively high equipment costs. Furthermore, their complex structure requires high maintenance skills, requiring regular servicing and maintenance by specialized technicians, which leads to the high maintenance costs. However, considering their high efficiency in complex machining tasks and the good result of high-quality products, the high long-term return on investment is vital for companies with a demand for high-end products and sufficient financial resources.

4. Processing Efficiency in Different Scenarios

For mass production of standard helmets, with its fast cutting speed and high flexibility, the robotic 3D laser cutting machine enables efficient mass production. Its relatively simple operation and convenient programming and adjustments allow for rapid switching between production models, offering significant processing efficiency advantages in this scenario.

For the customized production of small batches of high-precision, complex-shaped helmets, a 3D five-axis laser cutting machine might not operate as fast as robotic 3D laser cutting in large-scale production. However, it can complete complex, multi-step machining in a single setup, reducing workpiece turnaround time and setup errors, resulting in higher overall processing efficiency. This machine can quickly respond to customization needs, shorten production cycles while ensuring product quality, and meet customer demands for rapid delivery of personalized products.

Please refer to the table below for other differences

| Laser equipment | Robotic 3D laser cutting machine | 3D five-axis laser cutting machine |

| Movement mode | Six-axis robot + optional positioner (7-axis/8-axis) | Five-axis linkage machine structure |

| Flexibility | Extremely high, adaptable to special-shaped surfaces and non-standard helmet bodies | Medium, suitable for products with regular structures |

| Cutting path planning | Offline simulation programming, support for complex path simulation | CNC path programming, fixed path |

| Applicable products | Kevlar tactical helmets, multi-functional composite helmets | Standard electric motorcycle helmets, sports helmets, etc. |

| Batch production capacity | More suitable for flexible production of multiple varieties | More suitable for continuous batch production of single varieties |

| Investment of the system | Slightly higher initial investment, complex configuration | Relatively fixed structure, stable cost |

| Floor space | Small footprint, flexible layout | Large footprint, requires fixed installation |

| Operation and maintenance | Requires professional experience in robotics and laser simulation | Similar to traditional CNC, easy to operate |

The application of robotic 3D laser cutting machines and 3D five-axis laser cutting machines has significantly improved the production precision and quality consistency of helmets. In actual production, the two types of equipment complement each other rather than replace each other. A representative production line layout for a head protection equipment manufacturer is: a robotic 3D laser cutting machine performs the initial hole cutting of Kevlar blanks at the front end (prioritizing efficiency), a 3D five-axis machine handles the trimming of complex curved surfaces in the middle (prioritizing precision), and a robot performs the laser engraving of the logo at the back end (prioritizing flexibility). This combination increases the overall efficiency of the production line by 40% while meeting the technical requirements of different process steps.

In the emerging field of smart helmets, the synergy between the two equipments is even more important. In the processing of helmets with integrated AR display modules, robots cut the vent holes in the outer shell, while five-axis equipment precisely machines the internal circuit slots and sensor mounting points. The combination of these two processes allows the assembly error of the smart module to be controlled within 0.02mm, ensuring a distortion-free display. As laser power increases, the distinction between the two devices may become even more blurred. However, at the current technological stage, robotic 3D laser cutting machines are the "workhorse of flexible production," while 3D 5-axis laser cutting machines are the "benchmark of precision manufacturing." The combination of them leads the helmet industry transform from "qualified protection" to "ultimate safety."

Laser cutting injects intelligent power into helmet manufacturing

The helmet industry is in a critical period of transformation and upgrading, with safety performance, exterior structure, and user experience constantly being pushed to higher standards. Laser cutting is not only a reflection of technological advancement but also a key engine driving intelligent, digital, and flexible helmet manufacturing. It frees designers from the constraints of "process limitations" and enables them to transform innovative concepts related to safety and comfort into real products. Whether it's a robotic 3D laser cutting machine or a 3D five-axis laser cutting machine, their fundamental goal is to make every helmet safer, more precise, and more efficient. In the future, with the further integration of laser technology and industrial automation, the helmet industry will achieve leapfrog development in the field of intelligent manufacturing. For more further information, pls click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்