How to Select a Metalens in Laser Marking System

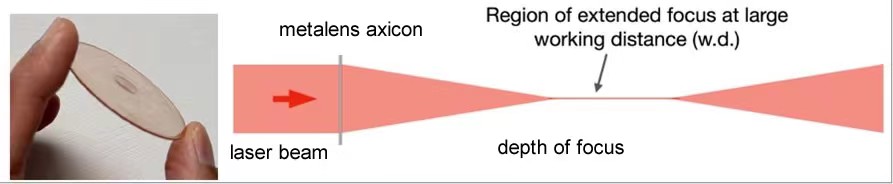

Metalenses are very suitable for laser processing, as they provide a long depth of focus and can easily and accurately mark and process various non planar objects.

Compared with traditional f-theta marking systems, the metalens marking system has the following advantages:

Ultra long depth of field (>75 mm), marking on non planar surfaces without the need for Z-axis movement, can also create consistent line width markings on non planar surfaces, especially suitable for 3D printing or non planar processing.

Due to the elimination of f-theta lens, the size of the scanning and marking head has decreased significantly.

Low cost, mass production.

Customizable metalenses for any laser wavelength.

Suitable for laser applications of all power levels, low-power laser applications can be used without coating.

Choosing a suitable metalens mainly considers laser wavelength, aperture (diameter of incident laser beam), effective focal length, depth of focus, diameter of focused spot, and laser power. At a laser power of around 50W, the metalens can operate stably without the need for coating. Choose the effective focal length based on the size of the marking area. The longer the focal length, the larger the marking area, but the larger the focusing spot. Therefore, it is necessary to choose a reasonable effective focal length.

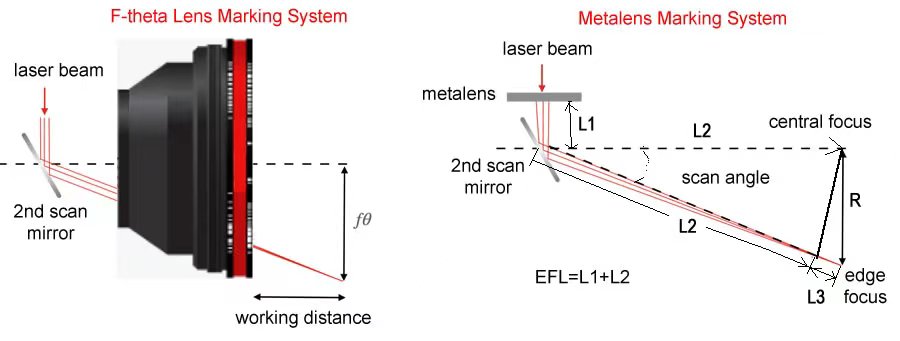

Assuming that the distance from the metalens to the second scanning mirror is L1, the distance from the second scanning mirror to the working surface is L2, and the effective focal length of the metalens is EFL, then EFL=L1+L2. If the maximum scanning angle of the galvanometer is θ, The distance between the center focus and the edge focus is the radius R of the marking area, R=TAN(θ)* L2, R, the defocus amount at the outermost edge called as L3 is L3=L2/COSIN(θ)- L2, the defocus amount should be less than 1/2 of the depth of focus, and the marking will be as clear and uniform as the marking on the focal plane.

Assuming the side length of the square marking area and the maximum scanning optical angle of the galvanometer is ± 20 degrees, assuming L1=50mm, calculate the center wavelength and defocus amount of the metalens ± L3 as shown in the table below. When selecting the effective focal length EFL of the metalens, the distance from L1, which is the distance from the metalens to the second scanning mirror, also needs to be considered. That is, some focal lengths of the metalens EFL=L1+L2.

Marking area side length mm | Marking area radius R mm | Maximum scanning angle θ | L2 mm | Effective focal length EFL mm | Defocus L3 mm |

50x50 | 35.36 | 0.35 | 97.14 | 147.14 | 6.23 |

75x75 | 53.03 | 0.35 | 145.71 | 195.71 | 9.35 |

100x100 | 70.71 | 0.35 | 194.28 | 244.28 | 12.47 |

125x125 | 88.39 | 0.35 | 242.84 | 292.84 | 15.59 |

150x150 | 106.07 | 0.35 | 291.41 | 341.41 | 18.70 |

200x200 | 141.42 | 0.35 | 388.55 | 438.55 | 24.94 |

250x250 | 176.78 | 0.35 | 485.69 | 535.69 | 31.17 |

300x300 | 212.13 | 0.35 | 582.83 | 632.83 | 37.40 |

350x350 | 247.49 | 0.35 | 679.97 | 729.97 | 43.64 |

400x400 | 282.84 | 0.35 | 777.10 | 827.10 | 49.87 |

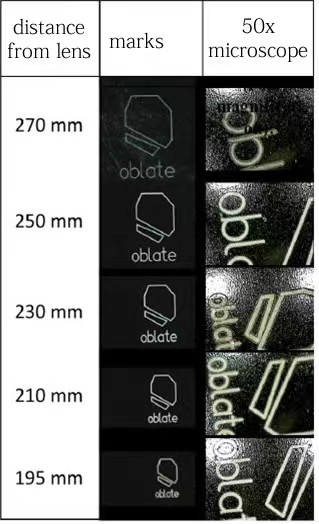

The following figure shows the marking effect at different distances between the marking surface and the metalens, with a defocus of up to 75mm, which can still be clearly marked.

The following table shows the range of some of our product parameters:

wavelength | Effective focal length EFL | Depth of focus (DOF) | diameter | Spot size |

355 nm | 25-100 mm | 25, 50 mm | 3-6 mm | 25-250 um |

532 nm | 25-100 mm | 25, 50 mm | 3-6 mm | 25-250 um |

1064 nm | 25-100 mm | 25, 50 mm | 3-6 mm | 25-250 um |

10.6 um | 25-100 mm | 25, 50 mm | 3-6 mm | 50-250 um |

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்