How Laser Cutting Machines Reshape Metal Foil Processing in 2025: 99% Yield Breakthroughs and $7.3B

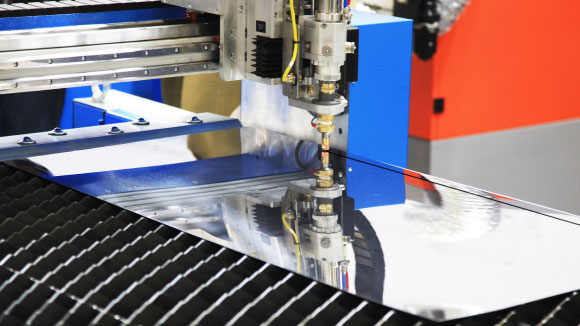

In a Shanghai battery factory, a 6μm copper foil strip glides through a laser processing zone at 15 meters/minute. Instead of metal debris, ultraviolet laser beams dance across the surface—creating 0.02mm-wide cuts with mirror-smooth edges and under 5μm heat-affected zones. This production line recently achieved 99.2% electrode tab yield, saving $4.2 million annually.

Laser cutting technology is revolutionizing metal foil processing with micron-level precision. By 2025, ultrafast laser equipment costs have dropped 40% from three years ago, driving adoption in ultra-thin foil processing from 15% (2023) to 25%. The global laser cutting machine market is expanding concurrently, projected to grow at a 6.5% CAGR from $4.2 billion in 2024 to $7.3 billion by 2034.

China's market demonstrates even stronger growth—laser cutting equipment sales reached ¥36.85 billion in 2024 and are expected to exceed ¥40 billion in 2025. This momentum stems from stringent precision requirements in new energy batteries, 5G communications, and medical devices. As copper foils thin to 0.006mm, traditional methods face insurmountable barriers: mechanical cutting produces burrs while chemical etching wastes material.

1. Technical Bottlenecks and Laser Breakthroughs

Metal foils (0.005-0.2mm thick) present three critical challenges in advanced manufacturing:

Burr formation: Mechanical die-cutting exceeds 30% burr incidence on foils <0.05mm, increasing short-circuit risks in batteries by 40%

Material waste: Chemical etching processes suffer 25% material loss rates, limiting copper foil utilization to ~60%

Thermal damage: Conventional lasers create >50μm heat-affected zones, reducing biocompatibility of medical implants

Laser cutting overcomes these through non-contact processing and precise energy control. For 6μm battery electrode foils, 355nm UV lasers achieve triple breakthroughs:

Kerf width reduced to 20μm with <1% burr rate

Material utilization increased from 60% to 85%

Processing speed reached 15m/min—5x faster than chemical etching

Economic Impact: A leading battery manufacturer implemented ultrafast lasers to boost electrode tab yield from 85% to 99.2%, adding 20 million pieces/year production capacity per line while reducing costs by 30%. This confirms laser technology's transition from "optional" to "essential.

2. Core Technologies and Equipment Selection

Laser cutting of metal foils relies on precise photothermal energy control—focusing beams into micron-scale spots to vaporize material instantaneously, assisted by gas to remove residue. Key 2025 laser technologies show differentiated advantages:

Table: Laser Technology Parameters for Metal Foil Processing

| Laser Type | Wavelength | Heat-Affected Zone | Thickness Range | Optimal Applications | 2025 Power Advancement |

| UV Laser | 355nm | ≤10μm | 0.01-0.1mm | Copper foil micro-drilling, FPC cutting | 300W pulsed modulation |

| Picosecond | 1064nm | 6-7μm | 0.05-0.2mm | Titanium alloy,aerospace parts | 24kW high-power systems4 |

| Femtosecond | 515nm | ≤1μm | 0.005-0.05mm | Medical stents, graphene films | <1ps ultra-short pulses |

Key Technical Advances:

Cold Processing: UV lasers limit thermal diffusion to <5μm, while pulse modulation increases absorption on high-reflectivity copper (>80%) to 65%

High-Power Innovation: TRUMPF's TruDisk 24001 (2022) achieves 24kW output, cutting 20mm metal plates at triple previous efficiency

Ultrafast Precision: Femtosecond pulses (<1ps) enable "cold ablation"—the only viable method for 0.01mm foils at ±1μm precision

Selection Strategy: Match materials to laser types—UV lasers (80-200W) for reflective metals (Cu/Al); picosecond lasers (150-300W) for high-melting-point materials (Ti alloy/stainless steel); femtosecond systems for medical-grade precision.

3. Process Optimization: From Microns to Sub-Microns

Laser cutting quality depends on four parameter interactions, requiring material-specific process databases:

Power Matching Principles

Copper foils: >80% reflectivity → pulsed modulation

Titanium alloys: Melting point 1668℃ → >200W base power

Stainless steel: 0.1mm thickness → 150W continuous wave

Speed and Gas Combinations

0.05mm aluminum: 20m/min + compressed air → 30% efficiency gain

0.1mm stainless steel: 10m/min + 99.99% nitrogen → zero oxidation

Medical titanium: 5m/min + argon shielding → biocompatibility assurance

Focus Positioning

Positive defocus (+0.1mm): Optimal for thin foil penetration

Negative defocus (-0.5mm): Depth control for thicker foils

AI Optimization Case: An electronics manufacturer processing 0.03mm LCP antenna substrates used machine learning to dynamically adjust parameters—cutting time decreased from 2s to 1.2s/piece while defect rate dropped from 5% to 0.3%. This demonstrates how parameter optimization directly boosts economic value.

4. Cross-Industry Applications and Economic Impact

New Energy Batteries: Yield Revolution

Technical breakthrough: UV lasers integrate cutting, forming, and deburring into one step

Economic value: Material utilization rose from 75% to 92%; one manufacturer reduced battery short circuits from 0.8% to 0.05%, saving >$1.5M/year

Capacity upgrade: Electrode tab cutting at 300mm/s enables 500,000 pieces/day per line

5G Communications: High-Frequency Component Fabrication

Flexible PCBs: 300mm/s cutting on 0.025mm PI films with <10μm heat-affected zones, enabling mold-free complex geometries

LCP antennas: ±3μm precision ensures 5G signal stability; prototyping cycles compressed from 72 hours to 4 hours

Cost efficiency: Prototyping costs reduced 90%, supporting consumer electronics' rapid iteration

Medical Devices: Implant Safety Advancements

Cardiac stents: Femtosecond lasers process 50μm-wide nickel-titanium alloy struts with <1μm heat impact, increasing endothelial cell adhesion by 20%

Minimally invasive catheters: 50μm holes on 1mm-diameter tubes with ±5μm positional accuracy, boosting assembly yield from 80% to 97%

Certification: Edge roughness Ra≤0.2μm meets medical standards, reducing thrombosis risk by 35%

Aerospace: Extreme Environment Solutions

Titanium foils: Picosecond-cut 0.05mm components withstand -196℃ liquid nitrogen impact tests without cracking

Satellite components: 3D path planning achieves ±10μm precision on curved surfaces, reducing satellite weight by 15%

Engine combustion tubes: Femtosecond-etched microstructures improve combustion efficiency by 12%

5. 2025 Trends: Intelligent and Green Manufacturing

AI-Driven Flexible Processing

Vision positioning: Automatic defect recognition with real-time path adjustment

Cloud process libraries: Self-optimizing parameters slash complex pattern programming time by 70%

Quality control: AI defect detection achieves 98% accuracy, reducing unplanned downtime by 60%

Low-Carbon Processing

Energy efficiency: Fiber laser cutters consume 40% less power than conventional systems

Fume management: Recycling systems provide 99.5% purification, complying with EU CE PED standards

Renewable integration: Photovoltaic direct-drive systems supply 35% of daytime energy

New Material Frontiers

Graphene films: <5μm kerf widths on 10μm films without damage

CFR composites: Ultrafast lasers enable aerospace applications

Metal-matrix composites: Picosecond lasers overcome delamination issues, improving efficiency by 50%

Market Outlook: The global ultrafast laser market grew at 70.5% CAGR from 2015-2019, dwarfing the 11% industry average. Policy tailwinds accelerate adoption—China's "Dual Carbon" goals list laser cutting in key technologies, with local governments offering up to 30% subsidies1. Driven by technology and policy, the industry is advancing toward its ¥40 billion target. If you want to know more further information, pls click here,

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்