Sintec 3D 5-Axis Laser Cutting Technology for Agile Industrial Manufacturing

In modern manufacturing, precise, efficient, and versatile material processing technologies are critical for innovation and market competitiveness. As a leading advanced processing method, 3D laser cutting technology has unlocked new possibilities – enabling unprecedented process innovation and complex part fabrication across industries.

3D laser cutting is a high-precision, flexible method utilizing a laser beam that moves freely across three axes to cut, drill, and mark complex geometries. Its principle relies on high-energy-density laser irradiation to locally melt or vaporize materials via non-contact processing, achieving intricate shapes through precise beam control.

As China’s laser technology pioneer, Sintec drives innovation through high-performance equipment. Our 5-axis laser cutting systems deliver breakthrough applications with high flexibility, intelligence, and precision, advancing Chinese manufacturing toward flexible, lean, and high-end production.

Sintec 3D 5-Axis Laser Cutting System Advantages:

1. Superior Beam Quality:

Stable power output with fine focus (spot diameter ≤0.1mm), producing narrow kerfs and smooth edges – eliminating secondary processing while reducing labor costs.

High Flexibility:Professional 5-axis CNC system enables 360° infinite rotation ±125° tilt for high-speed cutting of complex surfaces, 3D contours, and irregular parts.

2. Extreme Precision:

Dual-drive gantry structure with CE-certified welded steel frame ensures rigidity.

X-axis: Dual servo motors (imported) for synchronous drive

Z-axis: Aerospace-grade cast aluminum with high-precision reducer

Result: 0.1mm repeatability at 120m/min rapid traverse.

3. Wide Processing Range:

Max travel: 6000×2500×800mm (X/Y/Z) with auto-focus cutting head and rapid piercing.

4. Intelligent Operation:

Offline programming with collision detection & singularity avoidance

Expert process database and user-friendly HMI for simplified debugging.

5. Modular Design:

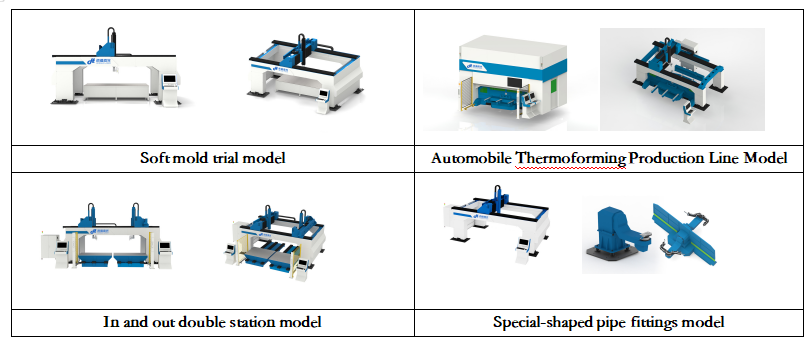

Configurable rotary/fixed worktables for diverse production needs.

Sintec 3D 5-axis laser cutting machine can realize the processing of complex curved parts, 3D parts, shaped parts, etc., such as waterjet cutting, fast trimming and high-speed piercing, etc., by virtue of the advantages of powerful flexibility, agility, automation and multi-material processing capability. Widely used in automobile manufacturing, mold manufacturing, engineering machinery manufacturing, elevator manufacturing, home appliance manufacturing, medical equipment and other industries, automotive thermoforming parts, 3D metal molding parts, curved parts, shaped tubes and other metal materials, three-dimensional precision high-speed cutting (hole cutting, edge cutting), and has become an important tool to enhance the core competitiveness of the customer's enterprise.

Sintec 3D 5-axis laser cutting machine adopts encapsulated dust-proof design to avoid dust and smoke from entering the optical system to affect the quality of the beam, protect the cutting effect of the product and prolong the service life of the optical system. Equipped with a dust extraction device, large wind power dust removal, can effectively suck away the particles of smoke and dust brought about by the cutting, so that customers can enjoy the cutting of intelligent manufacturing at the same time, to achieve environmental protection and clean production. With a very ingenious design concept and cost-effective, to help customers explore the unlimited possibilities of industrial flexible manufacturing. For more further information, pls click here.

English

English Français

Français Deutsch

Deutsch euskara

euskara Русский язык

Русский язык Italiano

Italiano Português

Português Nederlands

Nederlands Polski

Polski Greek

Greek Lietuva

Lietuva Türkçe

Türkçe 日本語

日本語 한어

한어 中文

中文 தாமில்

தாமில் فارسی

فارسی हिंदी

हिंदी Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Pilipino

Pilipino Indonesia

Indonesia தாமில்

தாமில்